Premium

POS Industry

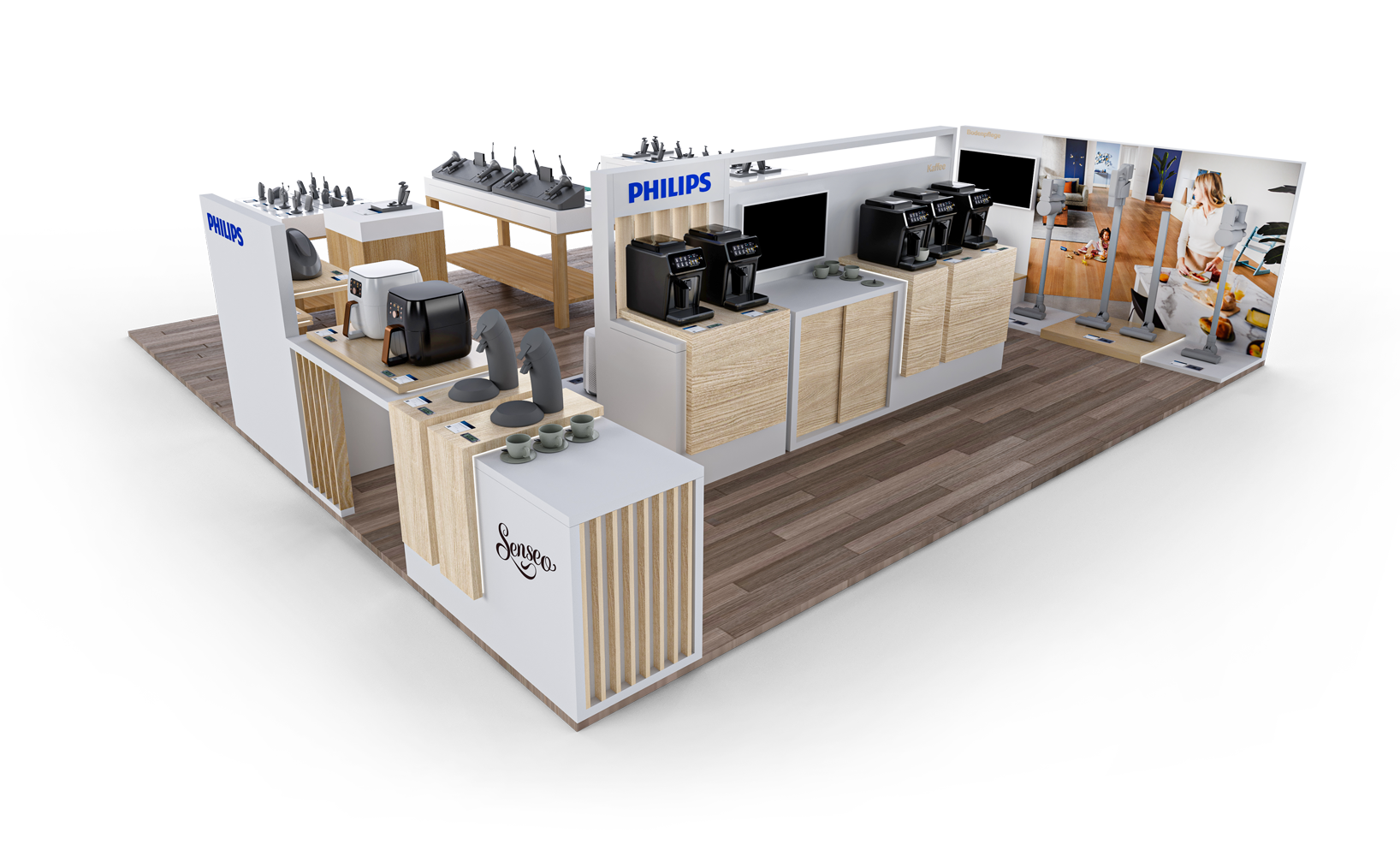

Retail is a part of everyday life, our goal is to create a memorable and exceptional experience for shoppers.

Technology & Efficiency

Technology is the key to achieve our objectives: growth, improving efficiency and implementation processes and therefore delivery times and new product development. We want to offer our employees safety and our customers an optimal price-performance ratio and, of course, we also want to do our part for the environment.

More planet

Less waste.

Circular, sustainable, and responsible economy is not negotiable. It is the future that came, and we play by its rules, setting new standards in doing business by reducing the usage of non-renewable resources, but also the waste from the production processes.

Partners

Latest news

04 / Apr / 2024

Charting New Frontiers: Our Visit to Google HQ

In a milestone journey to the United States, our team was granted the extraordinary opportunity to visit the Google Headquarters in California. This visit marks a pivotal moment in our year, as we celebrate our collaboration with Google...

18 / Dec / 2023

Our Journey with Google's Pixel 8 Launch

We are excited to share some fantastic news from our team! We've recently wrapped up an exhilarating project with Google, centered around the launch of the innovative Google Pixel 8 phones. This venture was not just a task; it was an...

10 / Nov / 2023

Celebrating a Milestone: Our Achievement of the AAA Platinum Creditworthiness Award

We are delighted to share a moment of pride and accomplishment with all of you. Recently, we have been honored with the prestigious AAA Platinum Creditworthiness award by Dun & Bradstreet Awards for Excellence, a recognition that...

27 / Oct / 2023

Introducing "POS Garden": Our Leap Towards Greener Retail Solutions

Innovation Meets SustainabilityIn an era where environmental consciousness is paramount, our company is proud to unveil "POS Garden," a groundbreaking initiative led by our ingenious industrial designers, Milena and Milos. Recognizing...

05 / Sep / 2023

Making waves in the tobacco industry

IQOS, the heat-not-burn tobacco device, is making waves in the tobacco industry with its fresh new branding approach. By focusing on simplicity and elegance, IQOS is captivating a new generation of customers who seek a healthier and...

01 / Jun / 2023

Exciting Announcement POPAI 2023

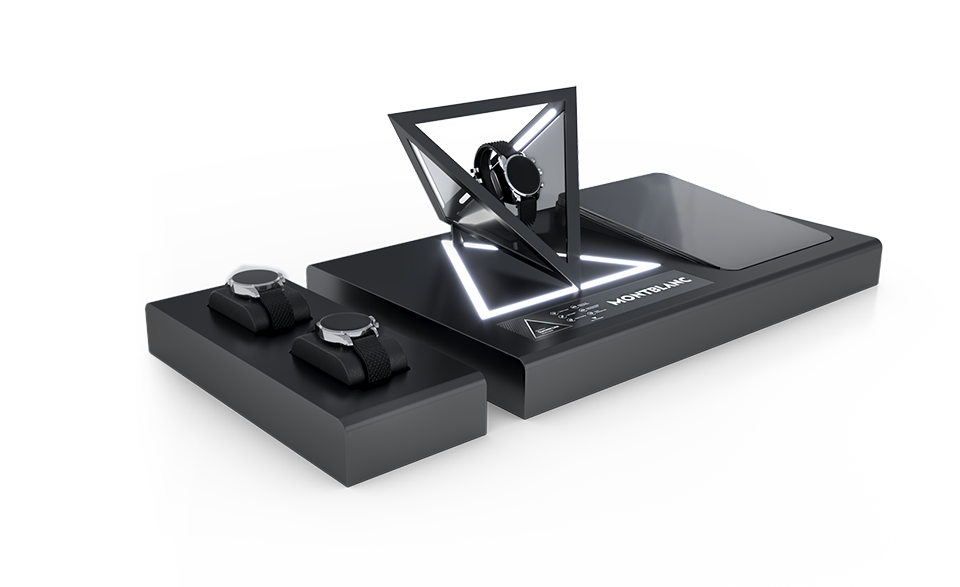

We are thrilled to share that we have won two POPAI Bronze Awards in two categories in the DACH region: Luxury Item Display and Shop-in-Shop!In the Luxury Item Display category, our unique Montblanc Summit 3 display stole the spotlight...